- 24 Nov 2022

- Patrick Ryan

- Multi-Mission Aircraft

The Kit & Equipment of Aerial Work Aviation

What makes an Aerial Work aviation aircraft a workhorse? The unobserved answer is the hardware and software that converts a General Aviation (GA) or Executive Jet into an aircraft that goes beyond flying people for hobby or transporting tourists to their next holiday.

Back to Articles

The kit & equipment of Aerial Work aviation is the "game-changer" when providing down-to-earth services that make a significant difference in many industries. Suppose you want to know what makes a basic airplane a workhorse. In that case, Patrick Ryan will guide you through the "specification" of the primary kit & equipment that makes a basic aircraft into something other than an aerial transport vehicle.

At the beginning of aviation history, it became apparent man wanted to do more than take a passenger or airmail from point A to point B, but leverage the latest technology to satisfy curious ideas or gain a business advantage. The world of Aerial Work (AW) aviation came about because of this passion or hindsight to utilize aircraft (manned & unmanned) with special kits & equipment to go beyond the basics of just transporting people or goods.

Along with this, the kit & equipment of Aerial Work aviation has evolved over the decades from simple mechanical devices, components, and instruments to disruptive deep-tech or high-tech systems. Like the world in general, Aerial Work aviation has definitely transitioned from the "Analog" ages to the "Digital" era with many more options and capabilities that the Wright Brothers could never have imagined.

With the advantages of digitalization, systems and components are smaller, lighter, and relatively inexpensive to obtain and operate. Because of this, complex mission or utility equipment is no longer an afterthought or wish. The primary operational kit & equipment aboard Aerial Work aircraft is readily available to small and large Aerial Work firms, i.e., it's no longer something militaries or governments could only afford. Furthermore, to put things into perspective, some of the high-end kit & equipment used today are often more expensive than the aircraft itself.

To understand what precisely is the kit & equipment of Aerial Work aviation, let's review the definition of AW kit & equipment and follow through with who makes and flies with these specialized components and systems.

What is Aerial Work Kit & Equipment?

In Aerial Work aviation, specialized kit & equipment means all devices, sensors, accessories, and assemblies designed and used for specific Aerial Work operations, including any associated avionics, furnishings, displays, accessories, components, and software. Aerial Work kits & equipment are the specialized gear or systems that are specific resources serving to equip operators for a particular purpose. Specifically, AW kit & equipment is either mechanical or electrical devices.

Mechanical Devices – Aerial Work mechanical devices comprise a mechanism that works on mechanical principles. Specifically, Aerial Work mechanical systems can consist of manual camera lifts, Aerial Firefighting water buckets, helicopter rescue hoists, Aerial Advertising banner towing gear, and many more types of hardware. Additionally, included in these devices are specialized brackets and housing elements for such devices, e.g., carbon fiber radar domes, exterior equipment pods, sensor mounts, etc.

Electrical Devices – Aerial Work electrical devices consist of systems that functionally rely on electric power to run their core parts (electric motors, sensors, onboard computers, monitors, communication receivers & emitters, software, etc.). Regarding specific electrical devices in Aerial Work operations, this can encompass everything thing from:

• Electro-Optical/Infra-Red (EO/IR) sensors.

• Searchlights.

• Augmented Reality (AR) map overlays.

• Rescue hoist

• Telecommunication signal receivers.

• Aerobatic smoke systems

• Mission management software.

• And many more… All of which have brought the digital world to the Aerial Work cockpit.

High-Tech, Low-Tech & Deep-Tech

Besides the basic definition of Aerial Work kit & equipment, the type of technology applied has and will make a significant difference in matching the right technical solution to the appropriate AW work-at-hand. To maximize output for every flight hour, the Aerial Work world leverages low-tech, high-tech, and even deep technology to achieve this goal.

Low-Tech - In general, low-tech devices can be designed and produced by anyone. Look around any flightline. Most basic but low-tech setups and devices support useful applications. These devices or setups could be a range of innovations from a simple Aerial Ash Scattering dispenser to a roll-on/roll-off (RORO) Airborne Sensor Operator workstation. Additionally, low-tech kit & equipment innovation is cheap and often used for practical purposes.

High-Tech - High-tech is a new technology with advanced features and capabilities, commonly focusing on particular problems for Aerial Work applications. High-tech reinvents core processes, operational models and changes performance on existing services, products, and the way of providing an aerial service. An excellent example is the introduction of aerial remote sensors (EO/IR, LiDAR, etc.). With an ever-growing number of smaller, affordable, and effective high-tech sensors available to the aviation community, many sectors of Aerial Work aviation are reinventing their business models and operational procedures.

Deep-Tech - Deep-tech solves major technical problems by tackling physical and intellectual issues. Deep-tech is revolutionary, a game-changer, and disruptive, but it takes a long time to implement in everyday flight operations. It also requires heavy capital investments and only works if there are technical and expertise that can support the considerable amount of research and development required. In the case of Aerial Work aviation, unmanned or robotic air vehicles (Drones) are one such deep-tech capability that has disrupted the Aerial Work community in the last couple of decades and will continue to do so in the future.

Who Flies With What Kit?

To give you a better perspective of the different types of kit & equipment the Aerial Work aviation sector utilizes, here are just a few particular AW sectors that leverage a variety of kit & equipment. Which involves both mechanical and electrical devices to maximize their potential or, better yet, to get the job done right the first time:

Aerial Surveying & Mapping

Aerial surveying collects data that uses aerial photography or remote sensing imaging from various electromagnetic spectrum bands, such as infrared, gamma, or ultraviolet. In aerial surveying, the goal is to obtain a complete and accurate image of the earth's surface below. There are several approaches for acquiring this data:

• Aerial Photography

• Remote Sensing Imaging

• Multispectral

• LiDAR

When it comes to the type of systems used in aerial surveying operations, systems like these are routinely integrated into an aerial surveying fix-wing, rotor-wing, or unmanned aircraft:

• Mounted Sensors – LiDAR, hyperspectral, digital cameras, etc.

• In-flight Data Recorders – Geospatial data (e.g., images, video, etc.)

• Data-Links – Air-to-Ground data relay communications.

• Digital Global Positioning Systems (DGPS) – Supplement and enhance the positional data available from global navigation satellite systems.

• Real-time Satellite Aircraft Position Tracking – monitoring aircraft or flight operations.

• And many more…

Flight Inspection

The Flight Inspection sector inspects, calibrates, and validates many aspects of the navigational aids and airway procedures currently operational worldwide. Thus, flight Inspection operations consist of "measuring" aeronautical facilities and systems. Plus "assessing" aeronautical procedures and the flying environment.

On the systems side of what the Flight Inspection sector utilizes, the backbone (outside of additional antennas integrated interference-free across the aircraft's fuselage) that makes it mission capable is the Flight Inspection System (FIS). In General, a FIS is a self-contained system with a navigation-grade inertial navigation system (INS), a barometric altimeter, a radar altimeter, GPS, and a TeleVision Positioning System (TVPS).

However, many FISs today go beyond the basics and provide these specific standard capabilities and more:

• Signal Receivers - Receivers for Flight Inspection and Flight Validation.

• Navigation Systems - Integration with cockpits from leading navigation systems for flight guidance & flight validation.

• Mapping Overlay Software - Multi-Mission Map systems mixed with mission information for real-time study replays and data recalculation.

• Onboard Wi-Fi - Tablet data interface via Wi-Fi for onboard multi-users, i.e., for additional Inspectors

• Real-Time Automatic Report Generation - High-quality color printouts of flight data and reports.

• Data Link - Transmitting and receiving real-time digital information.

• GNSS position reference systems - utilize satellite-based correction data services with global centimeter-level accuracy.

• High-Performance Computers - Process real-time data acquisition for accurate timing and calculations.

• And many more…

Aerial Surveillance

Relating to the aerial surveillance equipment operated in this sector, they rely on a slew of unique, leading-edge, and sophisticated systems that most other Aerial Work sectors don't have or will not obtain any time soon.

Some of the principal or typical types of systems and equipment you'll see integrated into an Aerial Surveillance aircraft (including unmanned aircraft) are:

• Electro-Optical Infra-Red (EO/IR) Systems – Hi-Definition (HD) Full Motion Video (FMV), Ground Moving Target Indication (GMTI).

• High-Performance Radar Systems – Synthetic- Aperture Radar (SAR)/ Inverse synthetic-aperture Radar (ISAR), GMTI.

• Automatic identification systems (AIS) Transponders – Automatic detection & tracking of sea vessels (similar to an aircraft transponder).

• Secure UHF/VHF Systems – Tactical voice communications.

• Long Range Line-of-Sight (LOS) Datalinks – Voice and HD video Tactical and Operational communications.

• Beyond-Line-of-Sight (BLOS) Datalinks – Voice and HD video distribution via satellite.

• Signals Intelligence (SIGINT) Systems – Communication & electronic systems monitoring, collection, geo-locating, and Direction Finding (DF).

• Aircraft Survivability Equipment (ASE) – Missile warning sensors and countermeasures dispensers.

• Identification Friend or Foe (IFF) – Cooperative Mark XII identification IFF, mode select (Mode S), and interface with the aircraft's traffic collision and avoidance system (TCAS).

• And many more…

Makers, Modifiers & Integrators of Aerial Work Kit

In the world of aviation kit & equipment, there are 'Makers,' and then there are 'Modifiers,' or sometimes they're 'Both.' In general, the 'Makers' design and manufacture the original aircraft or specialized system and component, i.e., referred to as Original Equipment Manufacturers (OEM) or Original Design Manufacturers (ODM). An illustration of these types of Multi-Mission kit & equipment OEMs and ODMs and their products are:

• Aerial Broadcasting Cameras & Lenses – GSS Cineflex V14, Shotover F1, Fujinon Premista series, etc.

• Maritime Patrol Automatic Identification Systems (AIS) Transponders – SAAB R5A

• Aerial Datalinks – SVP Aerospace, HDR-108 & AM-206

• Mounted Aerial Surveying Sensors – RIEGL, VP-1 HeliCopterPod

• Digital Global Positioning Systems (DGPS) – Cloud Cap Technology, Aircraft GNSS DGPS

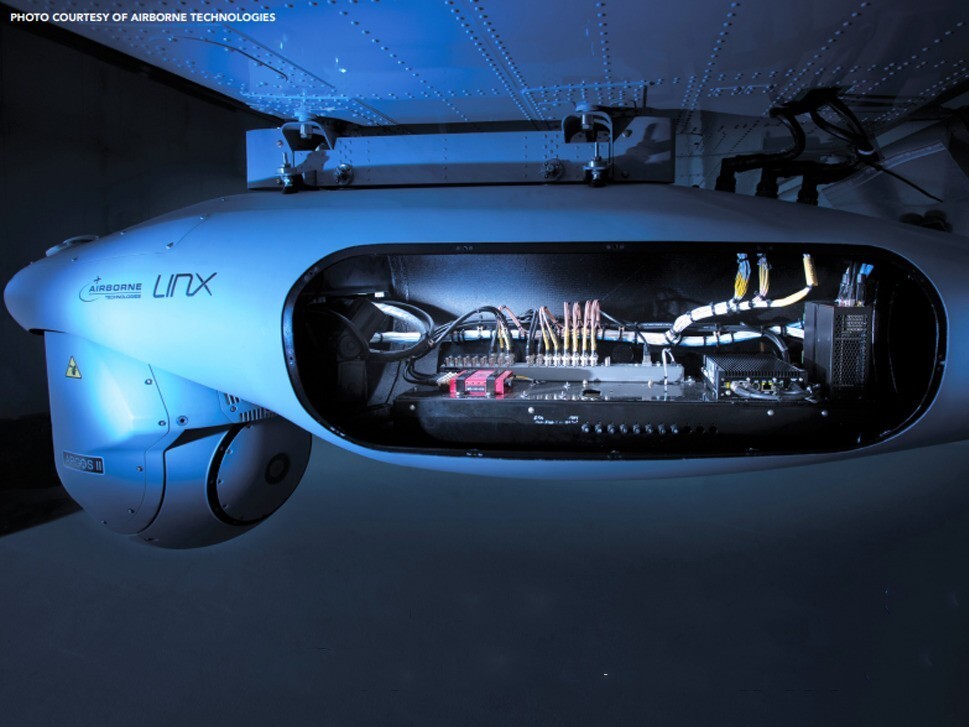

• Sensor Pods – Airborne Technologies, SCAR-Pod

• And many more…

The 'Modifiers & Integrators' are those organizations or companies that modify, alter, or integrate aircraft into special-purpose platforms. For example, converting a Boeing 747 into an Aerial Firefighting Water Bomber, outfitting a Bell 429 into a HEMS platform, etc. These firms are usually certified Maintenance and Repair Organizations (MRO), Design Organizations, or Production Organizations to provide 'Turn-Key' multi-mission upgrade solutions.

The type of modifiers and integrators range from large corporations to small firms. As an example, here are a few of the types of companies that focus on modifying or integrating the kit & equipment providing 'Turn-Key' Aerial Work aircraft solutions:

• Airborne Technologies - Austria

• BAE Systems - United Kingdom

• Summit Aviation - USA

• Nova Systems - United Kingdom

• Field Aviation - Canada/USA

• Diamond Aircraft - Austria

• And many more…

Without a doubt, the Aerial Work aviation sector could not do its job if it were not for the specialized kit and equipment required to accomplish a specific task. Because most aircraft are not built explicitly for every type of Aerial Work operation, unique systems and components are required to 'Turn-Key' these aircraft into a practical, effective, and safe utility platform.

Because Aerial Work aviation has a critical role in both aviation and in the world, the current and future need for remarkable low-tech, high-tech, and deep-tech mechanical & electrical capabilities adapted to both manned and unmanned aircraft will continue to expand at a rapid rate.

Again, Aerial Work aircraft are not mainly because of just the airframe, but more importantly, how they are technically equipped, modified, certified, and maintained by "Makers & Modifiers" to support their specific Aerial Work mission.

Next time you see an Aerial Broadcasting helicopter, Aerial Fire Fighting Water Bomber, Crop Duster, or even an Aerial Surveying & Mapping drone, think of the particular kit & equipment onboard. This could not happen without those specific companies, innovators, and technicians with the vision and skill to make special Aerial Work kit & equipment that benefits the aviation community and humanity.

See all of our Multi-Mission articles at our Multi-Mission Aircraft Hub

Related Articles

- 03 Nov 2022

- Patrick Ryan

- Multi-Mission Aircraft

- 05 Oct 2022

- Patrick Ryan

- Multi-Mission Aircraft